CSR for BCF Life Sciences

A long way, a challenge, a great human adventure!

We want to provide our employees, customers, suppliers and partners with the most transparent and complete information possible about the CSR actions we are successfully carrying out, as well as all those – many of them – on which we still have a lot of progress to make within Plant Care but also within BCF Life Sciences.

Much more than a duty, Corporate Social Responsibility poses an absolutely strategic question to managers: what contribution does the company wish to make to its ecosystem, whether it be to its employees, its territory, the society of which it is a part, and to the preservation of the planet’s resources?

4 major axes

to anchor this approach in our daily lives

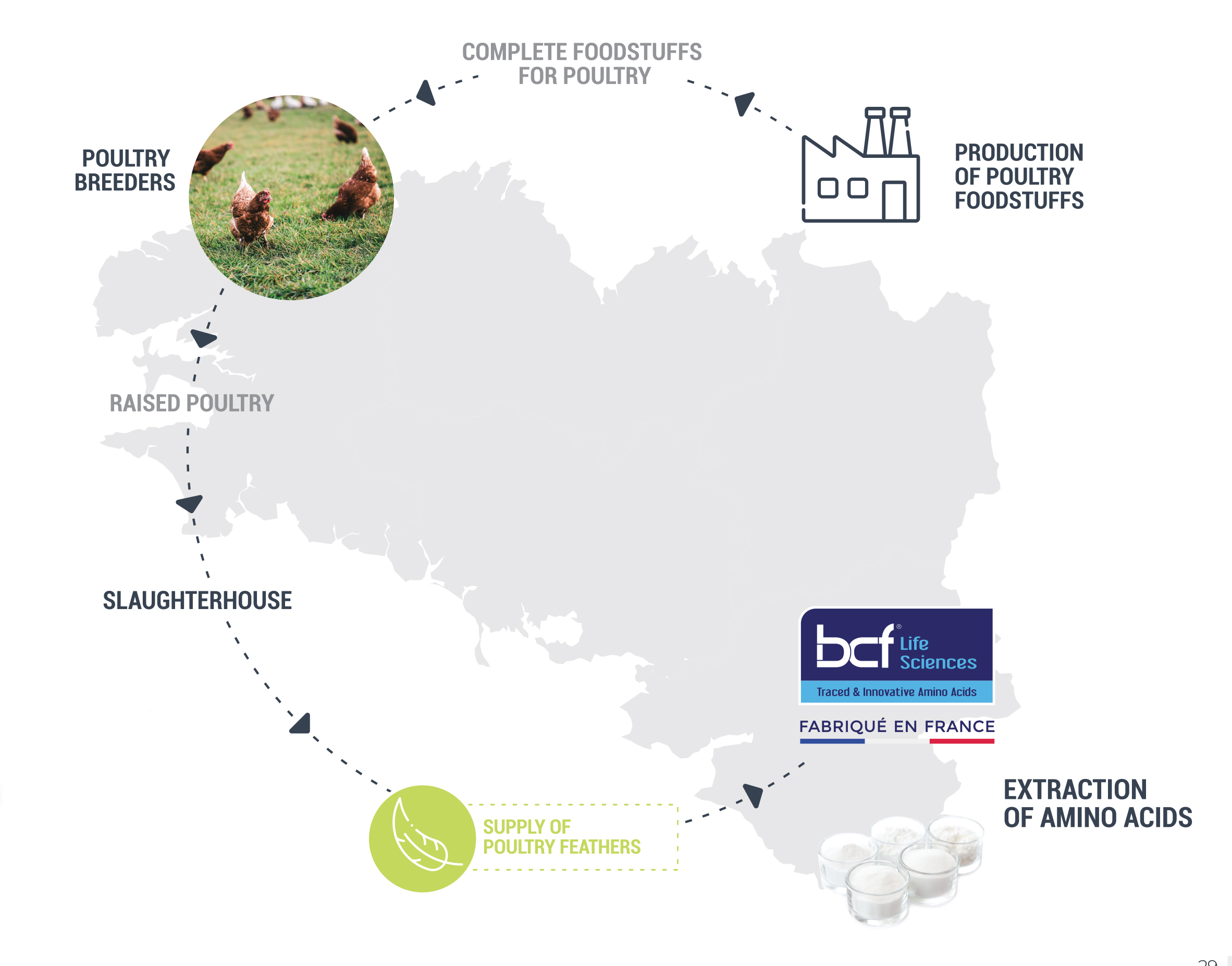

Our activities are born from the territorial circular economy.

Even today, the majority of our inputs can be considered as co-products of other industries.

BCF Life Sciences, a pioneer in the circular economy built around the Breton poultry industry.

BCF Life Sciences is a major partner in the French poultry industry, which includes chick hatching operations, poultry farmers, poultry feed producers, and processing plants for whole or cut-up fresh poultry and poultry-based ready-to-eat meals, representing a total of 50,000 jobs in France in 2019.

The valorization of co-products such as feathers represents one of the links in the chain’s value creation. In 2020, in the context of the COVID-19 crisis, BCF Life Sciences’ activity was recognized by the French government as “necessary for the proper functioning of the Nation”.

We have transparent targets and concrete actions to enable us to significantly reduce our carbon emissions.

Compared to the base year of 2021, we are committed to reducing our greenhouse gas emissions by 25% by 2027. Our goal will be achieved through a combination of short-term and longer-term actions.

We have always recovered heat generated by our process to reuse it in other operations. In 2022, we are continuing to improve the energy efficiency of our production techniques, including the installation of insulation on our equipment (from the valve to the reactor).

In the longer term, we are working to increase the amount of low-carbon energy we use and looking to develop new, more environmentally friendly processes.

Our commitments for the next few years:

- 12% reduction in gas consumption by 2023

- 30% energy consumption by 2027